The History of Cookware: From Clay Pots to Modern Innovations

- OLYTARU Enamel Stockpot with Lid,Simmer Pot,Flower Enamel Stockpot with Lid,Stockpots for Cooking(3L,growing)

- SOUJOY 3 Pack Porcelain Bakeware Set, Rectangular Baking Dishes, Lasagna Pan for Cooking, Kitchen, Casserole Dishes, Cake Dinner, Banquet and Daily Use

- Aiptosy Cool Cook 6 Pack Stainless Steel Coffee Spoon Ceramic Handle Teaspoon Sugar Ice Cream Desert Spoon Stirring Soup tableware

Cooking is a fundamental human activity, and throughout history, the tools we use to prepare our meals have evolved dramatically. From the earliest discoveries of fire to the ultra-modern kitchens of today, the history of cookware is a fascinating journey of innovation, necessity, and culinary creativity. Join us as we explore how our pots and pans transformed from simple vessels to sophisticated kitchen companions.

The Dawn of Cookware: Earth and Stone

Before dedicated cookware existed, early humans likely cooked directly on or in fires, or by heating stones and dropping them into water-filled animal hides or natural depressions. The true revolution began with the ability to shape materials.

Clay Pots: The Original Ovenware

The earliest true cookware emerged with the advent of pottery. Around 10,000 BCE, as humans settled and agriculture began, so did the need for more efficient food preparation and storage.

- How They Were Made: Early clay pots were hand-coiled or molded, then fired in open pits or simple kilns. This process hardened the clay, making it durable enough to withstand heat and hold liquids.

- Their Purpose: Clay pots were ideal for slow cooking, simmering, and boiling, allowing tougher ingredients to become tender. Their porous nature often allowed for a gentle, even heat distribution, akin to modern slow cookers.

- Key Characteristics: Porous, relatively fragile, and excellent at retaining heat once hot.

Stone Vessels: Durable but Difficult

While less common for everyday cooking than clay, various cultures also used carved stone bowls and vessels. These were incredibly durable and could withstand high heat, but they were heavy and difficult to shape, limiting their widespread use.

The Metal Ages: Strength, Durability, and Conductivity

The discovery and mastery of metals marked a colossal leap forward in cookware technology. Metals offered unparalleled durability, better heat transfer, and the ability to be shaped into a wider variety of forms.

Bronze: The First Metal Pans

With the Bronze Age (around 3300 BCE), metals like copper and then bronze began to be used for cooking vessels. Bronze was stronger and more durable than copper, allowing for larger, thinner-walled pots and pans. These were often cast or hammered into shape. While a significant improvement, bronze could react with acidic foods, imparting an off-flavor.

Iron: The Workhorse of the Kitchen

The Iron Age brought about arguably the most iconic and enduring material in cookware history: iron.

- Cast Iron: Around 6th century BCE in China, and later in Europe, cast iron cookware emerged. Its ability to retain and distribute heat incredibly well made it perfect for frying, searing, and baking. The porous nature of cast iron also allowed for “seasoning” – a layer of polymerized oil that created a natural non-stick surface over time.

- Key Characteristic: Exceptional heat retention, very durable, develops a natural non-stick surface with proper seasoning.

- Wrought Iron: Used for lighter pans, griddles, and early frying pans, wrought iron was hammered into shape. It was more forgiving to work with than cast iron for thin vessels but didn’t retain heat as well.

Copper: Beauty and Performance

By the Middle Ages, copper became a highly prized material for cookware, especially among the wealthy. Copper is an exceptional conductor of heat, meaning it heats up quickly and evenly, offering precise temperature control.

- The Catch: Copper is highly reactive with acidic foods, which can leach into food and cause discoloration or off-flavors.

- The Solution: Most copper cookware was lined with tin (and later, stainless steel) to prevent this reaction, allowing cooks to enjoy its superior heating properties safely.

- Key Characteristic: Unrivaled heat conductivity, but typically needs a non-reactive lining.

The Industrial Revolution & Beyond: Mass Production and New Materials

The Industrial Revolution (18th-19th centuries) transformed cookware production, making it more affordable and accessible. New materials and manufacturing techniques brought about even greater diversity.

Enameled Cookware: Marrying Form and Function

The 19th century saw the rise of enameled cast iron and steel cookware. A layer of glass (enamel) was fused to the metal surface. This solved several problems:

- Non-Reactive: The enamel provided a non-reactive, easy-to-clean surface, eliminating the need for tin lining in copper or seasoning in cast iron.

- Aesthetics: It allowed for a huge range of colors, bringing a new aesthetic to kitchens.

- Key Characteristic: Easy to clean, non-reactive, and aesthetically pleasing.

Aluminum: Lightweight and Affordable

Patented in 1888, aluminum cookware quickly gained popularity. It’s lightweight, an excellent heat conductor, and relatively inexpensive to produce.

- Advantages: Heats quickly, good for everyday use.

- Disadvantages: Can warp at high temperatures and react with acidic foods (though less so with modern alloys), and is prone to staining.

- Key Characteristic: Lightweight, good heat conductivity, and affordable.

Stainless Steel: The Modern Staple

Developed in the early 20th century, stainless steel became a ubiquitous material for cookware. It’s an alloy of steel and chromium, making it incredibly durable, non-reactive, and resistant to rust and corrosion.

- The Challenge: Stainless steel alone isn’t the best heat conductor.

- The Solution: Many modern stainless steel pans feature “clad” or “sandwich” bottoms – layers of aluminum or copper are fused between layers of stainless steel to improve heat distribution.

- Key Characteristic: Extremely durable, non-reactive, easy to clean, often with a core for better heat distribution.

Modern Innovations: Convenience, Specialization, and Performance

The latter half of the 20th century and the 21st century have seen an explosion of innovation, focusing on ease of use, specialized applications, and enhanced performance.

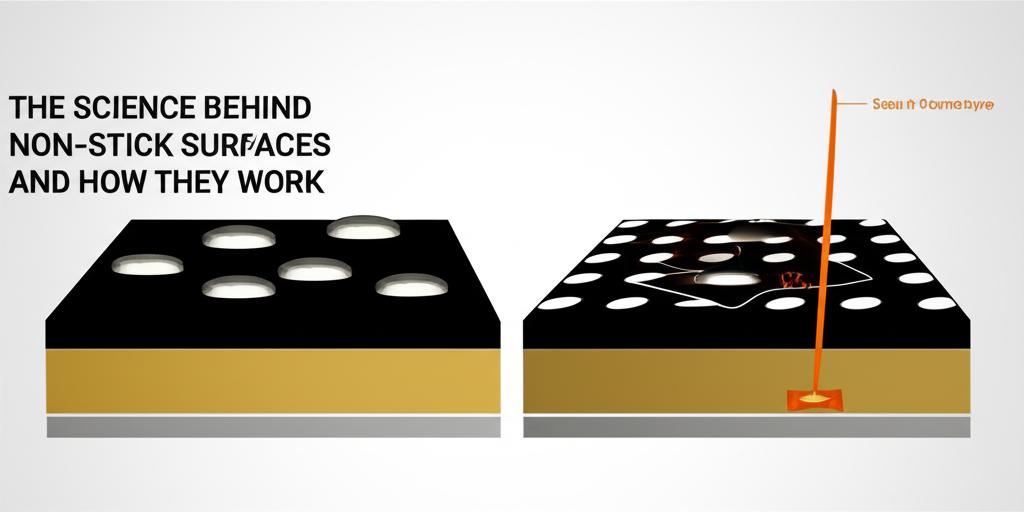

Non-Stick Coatings: The Convenience Revolution

The invention of non-stick coatings (like PTFE) in the mid-20th century revolutionized home cooking. Foods release easily, and cleanup is a breeze.

- Considerations: Non-stick surfaces can be delicate and require special care to prevent scratching and degradation. High heat can also damage them.

- Key Characteristic: Excellent food release, easy cleanup, but requires careful handling.

Silicone: Flexible and Versatile

Beyond traditional pots and pans, materials like silicone have found their niche, particularly in baking and specialized kitchen tools. Silicone is flexible, heat-resistant, and non-stick, making it ideal for bakeware, spatulas, and oven mitts.

Ceramic Cookware: Aesthetic and Functional

Modern “ceramic” cookware often refers to two types:

1. True Ceramic: Made from clay and fired at high temperatures, similar to ancient pottery but with modern glazing techniques that make it non-porous and durable. Great for slow, even cooking.

2. Ceramic Coatings: A ceramic-based non-stick coating applied to metal cookware. Often marketed as a “healthier” or more durable alternative to traditional non-stick, though their longevity can vary.

- Key Characteristic: Non-reactive, often non-stick, and can be very aesthetically pleasing.

Caring for Your Culinary Companions: Tips for Longevity

No matter the material, proper care is crucial to extend the life of your cookware and ensure it performs its best.

Step-by-Step General Cookware Care:

- Read Manufacturer Instructions: Always start here. Each type of cookware and even specific brands may have unique care requirements.

- Cool Down: Allow hot cookware to cool completely before washing. Sudden temperature changes (thermal shock) can warp metal pans or crack ceramic and enameled surfaces.

- Gentle Cleaning:

- For most non-stick, ceramic-coated, and enameled surfaces: Use a soft sponge, cloth, or nylon brush with warm, soapy water.

- For stainless steel and bare aluminum: A regular dish sponge is usually fine. For stubborn stains, specialized cleansers for these materials can be used.

- For seasoned cast iron: Scrape off food, rinse with hot water, and scrub with a stiff brush (no soap usually needed if well-seasoned). Dry thoroughly.

- Thorough Drying: Always dry your cookware completely after washing. This is especially critical for cast iron and carbon steel to prevent rust. Even stainless steel can develop water spots if not dried.

- Proper Storage:

- Hang pots and pans where possible to prevent scratching.

- If stacking, place a soft cloth, paper towel, or pan protector between each piece to prevent scratching, especially for non-stick or enameled surfaces.

Common Mistakes to Avoid:

- Using Metal Utensils on Non-Stick or Ceramic Coatings: This is a quick way to destroy the surface. Always use wood, silicone, or nylon utensils.

- Overheating Non-Stick Pans: High heat can degrade non-stick coatings and release fumes. Use medium heat settings for most non-stick cooking.

- Putting Hot Pans in Cold Water: As mentioned, thermal shock can warp or crack cookware. Be patient and let them cool.

- Using Abrasive Cleaners or Scouring Pads on Delicate Surfaces: This includes steel wool on non-stick, ceramic, or enameled surfaces. Stick to soft sponges or brushes.

- Not Seasoning Cast Iron (or re-seasoning when needed): If your cast iron loses its non-stick properties or starts to rust, it likely needs to be re-seasoned.

- Putting Cast Iron or Carbon Steel in the Dishwasher: The harsh detergents and prolonged moisture will strip the seasoning and cause rust. Always handwash and dry immediately.

- Using Cooking Sprays on Non-Stick: Some cooking sprays can build up a sticky residue that is hard to remove and can degrade the non-stick surface over time. Use a small amount of oil or butter instead.

Essential Tips for Cookware Longevity:

- Match Pan Size to Burner Size: This ensures even heating and prevents energy waste or overheating of pan handles.

- Preheat Properly: Many pans, especially stainless steel, perform best when preheated empty for a few minutes before adding oil and food. This helps prevent sticking.

- Clean Immediately After Use: The longer food sits, the harder it is to remove.

The journey of cookware mirrors the journey of human civilization – from basic needs to sophisticated desires. Each material and innovation has brought us closer to mastering the art of cooking, making our time in the kitchen more efficient, enjoyable, and delicious. By understanding the history of cookware and how to care for our tools, we not only preserve them but also honor the centuries of ingenuity that went into their creation.

- OLYTARU Enamel Stockpot with Lid,Simmer Pot,Flower Enamel Stockpot with Lid,Stockpots for Cooking(3L,growing)

- SOUJOY 3 Pack Porcelain Bakeware Set, Rectangular Baking Dishes, Lasagna Pan for Cooking, Kitchen, Casserole Dishes, Cake Dinner, Banquet and Daily Use

- Aiptosy Cool Cook 6 Pack Stainless Steel Coffee Spoon Ceramic Handle Teaspoon Sugar Ice Cream Desert Spoon Stirring Soup tableware

FAQ

Q. What materials were used for the earliest forms of cookware?

A. The very first forms of cookware were predominantly made from natural materials readily available to early humans. This included clay, which was shaped into primitive pots and then hardened by fire, and stones, which were heated and used directly for cooking or within vessels to boil water.

Q. When did metal cookware become prevalent, and which metals were initially adopted?

A. Metal cookware began to emerge significantly during the Bronze Age, around 3000 BCE, with bronze being one of the first metals extensively used for its durability and malleability. Later, during the Iron Age, iron became a dominant material due to its abundance and strength, leading to the widespread use of cast iron pots and pans. Copper also played a crucial role due to its excellent heat conductivity.

Q. What significant innovations transformed cookware design and functionality over the centuries?

A. Key innovations include the development of glazing for pottery to make it non-porous and easier to clean, the introduction of enameling to protect iron from rust and provide a smoother cooking surface, and the invention of non-stick coatings in the mid-20th century. More recently, advancements in stainless steel alloys, aluminum, and the development of induction-compatible materials have further revolutionized cookware.

Q. How did the evolution of cookware influence culinary practices and the types of food prepared?

A. As cookware evolved, so did the range of culinary techniques. The advent of waterproof clay pots allowed for boiling and stewing, expanding dietary possibilities. Durable metal pans enabled efficient frying, sautéing, and searing. The development of heat-retentive bakeware made ovens more versatile, leading to a wider array of baked goods and roasted dishes. Each material innovation opened new doors for food preparation and broadened human diets.

Q. What are some popular modern cookware materials, and what are their primary advantages?

A. Popular modern cookware materials include stainless steel (durable, non-reactive, easy to clean), cast iron (excellent heat retention, even heating, naturally non-stick when seasoned), non-stick coatings (easy food release, less oil needed), copper (superior heat conductivity, precise temperature control), and various ceramic or ceramic-coated options (non-reactive, often non-stick, good heat distribution). Each material offers distinct advantages suited to different cooking needs and preferences.

Q. What future trends are anticipated in the development of cookware?

A. Future trends in cookware are likely to focus on enhanced sustainability through recycled or biodegradable materials, improved energy efficiency for faster and more even cooking, and lighter yet highly durable designs. We may also see “smart” cookware integrated with sensors or Bluetooth technology to assist with precise temperature control and cooking times, as well as more modular and customizable systems.