The Science Behind Non-Stick Surfaces: Unveiling the Magic for Effortless Cooking

- BELLA XL Electric Ceramic Titanium Griddle, Make 15 Eggs At Once, Healthy-Eco Non-stick Coating, Hassle-Free Clean Up, Large Submersible Cooking Surface, 12″ x 22″, Copper/Black

- Tramontina Professional 10-Inch Non Stick Frying Pan, Heavy-Gauge Aluminum Skillet with Reinforced Nonstick Coating, Red Handle, Dishwasher and Oven Safe

- SENSARTE Nonstick Frying Pan Skillet, Swiss Granite Coating Omelette Pan, Healthy Stone Cookware Chef’s Pan, PFOA Free (8/9.5/10/11/12.5 Inch) (10 Inch)

Imagine effortlessly flipping a pancake without it sticking, or sliding scrambled eggs directly from the pan to your plate with barely a residue left behind. That’s the daily magic of non-stick cookware! But what truly makes these surfaces so slippery and easy to clean? It’s not just a coating; it’s a fascinating blend of chemistry, physics, and engineering.

In this detailed guide, we’ll dive deep into the science that makes non-stick surfaces work, give you step-by-step tips for optimal use and care, and help you avoid common mistakes to keep your cookware performing like new.

The Sticky Problem: Why Does Food Stick in the First Place?

Before we understand how non-stick works, let’s briefly look at why food sticks. When you cook, food naturally wants to form chemical bonds with the metal surface of your pan. This phenomenon is called adhesion. At a microscopic level, both the food and the pan have tiny imperfections and atomic forces that pull them together.

Think of it like this: if you have a very rough surface, things can “grip” onto it more easily. Also, materials have something called surface energy. Surfaces with high surface energy (like bare metal) are more “attractive” to other molecules, making food more likely to stick.

The Non-Stick Solution: Lowering Surface Energy and Friction

Non-stick surfaces are designed to counteract adhesion by fundamentally changing the pan’s surface properties. They achieve this in two key ways:

- Extremely Low Surface Energy: Unlike metals, non-stick coatings are made from materials with very low surface energy. This means they are inherently less “attractive” to other molecules, including your food. Food simply doesn’t want to form strong bonds with these surfaces.

- Low Coefficient of Friction: These materials are incredibly smooth and slippery, minimizing the physical friction between the food and the pan. This allows food to glide off easily.

The Chemical Marvels: What Are Non-Stick Coatings Made Of?

While there are a few types, the most common and widely recognized non-stick material is Polytetrafluoroethylene (PTFE). You might know it by its brand name, Teflon®, which popularized its use.

-

PTFE (Polytetrafluoroethylene): This remarkable synthetic fluoropolymer is the king of non-stick. Its magic lies in its molecular structure. PTFE consists of long chains of carbon atoms completely surrounded by fluorine atoms.

- Strong Carbon-Fluorine Bonds: The fluorine atoms create a very stable, tightly packed shield around the carbon chain. These bonds are incredibly strong and repel almost everything.

- Chemical Inertness: This strong shielding makes PTFE chemically inert, meaning it doesn’t react with most substances, including acids, bases, and, most importantly, your food.

- Hydrophobic and Oleophobic: PTFE is both hydrophobic (water-repelling) and oleophobic (oil-repelling). Water and oil droplets bead up and roll off the surface, taking any food particles with them, making cleanup a breeze.

- Low Friction: The smooth, uniform surface of PTFE also contributes to its extremely low coefficient of friction, making it one of the slipperiest solids known to man.

-

Ceramic-Based Coatings: These are often marketed as “green” or “eco-friendly” alternatives. They are typically made from silica (a derivative of sand) applied through a sol-gel process. While they offer good non-stick properties initially and can withstand higher temperatures than traditional PTFE, they tend to be less durable over time and may lose their non-stick properties faster with improper care. They are generally not as slick as PTFE.

-

Silicone Coatings: Primarily used for bakeware, silicone is another polymer known for its flexibility, heat resistance, and non-stick qualities. It’s excellent for baking sheets and molds where flexibility is an advantage.

How Non-Stick Coatings Are Applied: A Simplified Look

Applying a durable non-stick coating isn’t as simple as just painting it on. It’s a multi-step industrial process:

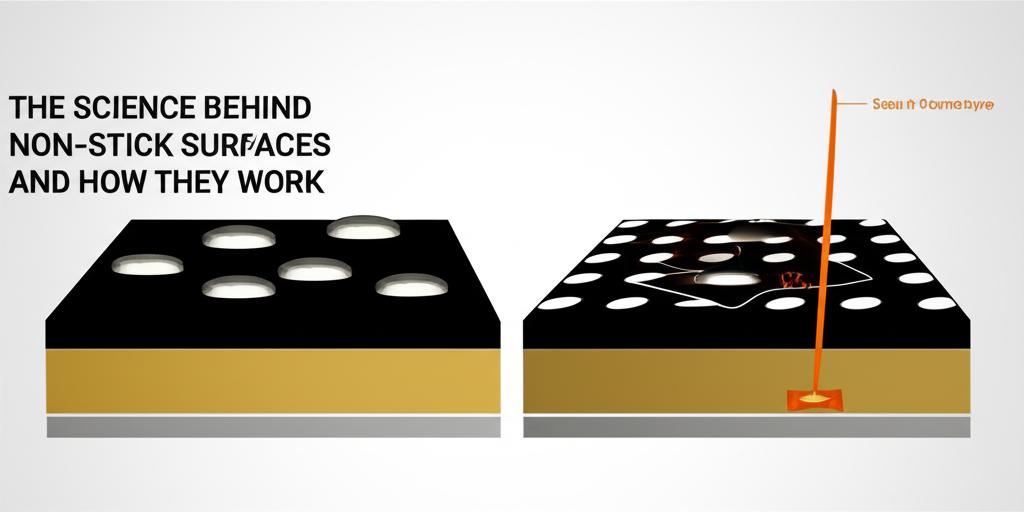

- Surface Preparation: The metal pan (often aluminum or stainless steel) is thoroughly cleaned and then mechanically roughened. This roughening creates a textured surface with tiny pores and valleys, giving the non-stick coating something to grip onto. Think of it like priming a wall for paint – you want a surface that the paint will adhere to well.

- Primer Application: A special primer layer is sprayed onto the prepared metal. This primer contains materials that bond well to both the metal and the subsequent non-stick layers.

- Non-Stick Topcoat Application: One or more layers of the non-stick material (like PTFE) are then applied. High-quality cookware often features multiple layers to enhance durability and performance.

- Curing/Baking: The coated pan is then baked at high temperatures. This curing process fuses the layers together and permanently bonds them to the pan’s surface, creating a durable, non-stick finish.

Beyond the Coating: The Importance of the Pan’s Base Material

While the non-stick coating gets all the glory, the base material of the pan plays a crucial role in its overall performance and longevity.

- Aluminum: Lightweight and an excellent heat conductor, aluminum is a popular choice for non-stick cookware. It heats up quickly and evenly, which is vital for preventing hot spots that can damage the non-stick coating.

- Stainless Steel: Often used with an aluminum core (clad construction), stainless steel provides durability and magnetic properties (for induction cooktops). While not a great heat conductor on its own, when combined with aluminum, it creates a robust and evenly heating pan.

Even heat distribution is key! If a pan heats unevenly, hot spots can form, causing food to stick in those areas and accelerating the breakdown of the non-stick coating.

Mastering Your Non-Stick Cookware: Tips for Longevity and Performance

Understanding the science is great, but knowing how to properly use and care for your non-stick surfaces is what truly makes them last. Follow these steps and tips to extend the life of your non-stick pans and ensure effortless cooking every time.

Step-by-Step Care & Use:

1. Before First Use:

- Wash Thoroughly: Always wash your new non-stick pan with warm, soapy water and a soft sponge before its first use. Rinse completely and dry.

- Optional – Seasoning: Some manufacturers recommend a light seasoning for initial protection, though it’s less critical for modern PTFE coatings. To season:

- Place the clean, dry pan on the stovetop over low heat for 30 seconds.

- Remove from heat and add one teaspoon of cooking oil (like vegetable, canola, or grapeseed).

- Using a paper towel, carefully wipe the oil all over the interior surface of the pan.

- Let the pan cool completely. Wipe off any excess oil before storing.

2. While Cooking:

- Choose the Right Heat Setting: Medium-low to medium heat is your non-stick pan’s best friend. High heat can cause the coating to degrade over time and warp the pan. Non-stick pans conduct heat efficiently, so you often need less heat than with traditional stainless steel or cast iron.

- Use Proper Utensils: This is crucial! Only use silicone, wood, or heat-resistant plastic utensils. Metal utensils will scratch and damage the non-stick coating, rendering it useless.

- Use a Little Oil (Optional): While non-stick means food won’t stick, a small amount of oil or butter can enhance flavor and help with browning. Avoid aerosol cooking sprays, as they can build up a sticky residue that’s difficult to remove and can damage the coating.

- Avoid Overheating Empty Pans: Never leave an empty non-stick pan on a hot burner. This can cause the pan to overheat rapidly, potentially damaging the coating and releasing fumes.

3. Cleaning and Care:

- Let it Cool Down: Always let your non-stick cookware cool down completely before washing. Submerging a hot pan in cold water can cause thermal shock, leading to warping and damage to the coating.

- Handwash is Best: Handwashing is highly recommended for extending the life of your non-stick pans, even if they are labeled “dishwasher safe.” Dishwasher detergents can be abrasive and the high heat cycles can prematurely degrade the coating.

- Gentle Cleaning: Use warm, soapy water and a soft sponge or cloth. For stubborn bits, let the pan soak for a few minutes to loosen the residue. Avoid abrasive scrubbers, steel wool, or harsh cleaning chemicals.

- Thorough Drying: Dry the pan completely before storing to prevent water spots and potential residue buildup.

4. Storage:

- Protect the Coating: To prevent scratches and damage, do not stack non-stick pans directly on top of each other without protection. Use pan protectors, paper towels, or soft cloths between pans if you must stack them. Hanging pans is an excellent way to protect them.

Common Mistakes to Avoid:

- Using Metal Utensils: The #1 killer of non-stick coatings. Just say no to metal.

- High Heat Cooking: Overheating degrades the non-stick properties and can damage the pan itself.

- Aerosol Cooking Sprays: These can leave a gummy residue that’s tough to clean and can cause food to stick.

- Washing Hot Pans: Thermal shock causes warping and shortens lifespan.

- Dishwasher Use: Harms the coating over time, despite “dishwasher safe” claims. Handwash for longevity.

- Using Abrasive Cleaners or Scouring Pads: Scratches away the non-stick layer.

- Stacking Pans Without Protection: Leads to scratches and chips.

When to Say Goodbye:

Even with the best care, non-stick coatings have a finite lifespan. It’s time to replace your pan if:

- The coating is visibly flaking, peeling, or bubbling.

- There are significant scratches or gouges exposing the metal underneath.

- Food consistently starts to stick, even with proper use and care.

Safety First: Are Non-Stick Surfaces Safe?

This is a common and important question. Modern non-stick cookware is considered very safe for everyday use.

- PFOA-Free: Concerns about PFOA (Perfluorooctanoic Acid) led to its global phase-out. Modern non-stick coatings are PFOA-free, and have been for many years.

- Overheating Concerns: If a non-stick pan is heated to extremely high temperatures (typically above 500°F / 260°C – much hotter than normal cooking temperatures), it can release harmless fumes that might cause temporary, flu-like symptoms in some people (sometimes called “Teflon flu”). This is highly unlikely to happen during normal home cooking, especially if you follow the advice to use medium-low to medium heat. Good ventilation in your kitchen is always a good idea, regardless of the cookware you use.

Conclusion: Embrace the Effortless Cook

The science behind non-stick surfaces is a marvel of material engineering, turning everyday cooking into an effortless joy. By understanding how these coatings work – through their incredibly low surface energy, chemical inertness, and slick friction-reducing properties – you’re empowered to make the most of your cookware.

With proper care, focusing on gentle heat, soft utensils, and careful cleaning, your non-stick pans will continue to deliver delightful, stick-free results for years to come. So go ahead, cook with confidence, and enjoy the magical simplicity of non-stick!

- BELLA XL Electric Ceramic Titanium Griddle, Make 15 Eggs At Once, Healthy-Eco Non-stick Coating, Hassle-Free Clean Up, Large Submersible Cooking Surface, 12″ x 22″, Copper/Black

- Tramontina Professional 10-Inch Non Stick Frying Pan, Heavy-Gauge Aluminum Skillet with Reinforced Nonstick Coating, Red Handle, Dishwasher and Oven Safe

- SENSARTE Nonstick Frying Pan Skillet, Swiss Granite Coating Omelette Pan, Healthy Stone Cookware Chef’s Pan, PFOA Free (8/9.5/10/11/12.5 Inch) (10 Inch)

FAQ

Q. What is the primary material responsible for the non-stick property of most cookware?

A. The most common material used for non-stick surfaces is Polytetrafluoroethylene (PTFE), widely recognized by the brand name Teflon™. PTFE is a synthetic fluoropolymer characterized by its strong carbon-fluorine bonds, which are incredibly stable and non-reactive. This unique molecular structure gives PTFE an extremely low surface energy, making it both hydrophobic (water-repelling) and oleophobic (oil-repelling), effectively preventing food from adhering.

Q. How is the non-stick coating applied to cookware, and what contributes to its durability?

A. Non-stick coatings are typically applied in a multi-layer system. First, the metal substrate (usually aluminum or stainless steel) is mechanically roughened, for instance, by sandblasting, to create a textured surface that improves adhesion. Then, one or more primer coats containing adhesive resins are sprayed on, followed by topcoats that contain the PTFE particles. After application, the cookware is baked at high temperatures (around 400°C or 750°F) to cure the coating, creating a durable bond between the layers and the pan. The multi-layer approach enhances both the adhesion to the metal and the overall wear resistance of the non-stick surface.

Q. Why doesn’t food stick to these surfaces at a molecular level?

A. At a molecular level, the non-stick property stems from the extremely low surface energy of materials like PTFE. Surface energy refers to the cohesive forces present at a material’s surface. Materials with low surface energy minimize interactions with other molecules. When food comes into contact with a non-stick surface, the cohesive forces within the food molecules themselves are much stronger than the adhesive forces between the food and the coating. This causes liquids to bead up and solids to release easily, as the non-stick surface actively repels chemical bonding with fats, proteins, and carbohydrates found in food.

Q. Are non-stick coatings safe, especially concerning chemicals like PFOA and PFOS?

A. Modern non-stick cookware from reputable manufacturers is widely considered safe for everyday use. Historically, perfluorooctanoic acid (PFOA) and perfluorooctane sulfonate (PFOS) were used as processing aids in the production of some non-stick coatings. However, these chemicals have been phased out globally due to environmental and health concerns. Today’s non-stick coatings are PFOA and PFOS-free. The primary safety concern with non-stick coatings relates to overheating; if pans are heated above approximately 500°F (260°C), the coating can begin to degrade, potentially releasing fumes that, in rare instances, can cause temporary flu-like symptoms (polymer fume fever) in humans and are harmful to birds. Under normal cooking temperatures, non-stick cookware is stable and poses no risk.

Q. Besides PTFE, what other materials are used for non-stick surfaces, and how do they work?

A. While PTFE is the most common, other materials offer non-stick properties. Ceramic non-stick coatings are often made using sol-gel technology, which involves a silicon-dioxide (silica) based material cured at high temperatures to form a hard, smooth, non-porous layer. These coatings are typically PTFE-free and create a non-stick surface through their inherent smoothness and low friction. Anodized aluminum cookware, created through an electrochemical process that hardens the surface, offers some natural stick resistance, though less than dedicated non-stick coatings. Silicone is also widely used in bakeware, providing flexibility and a naturally low-adhesion surface due to its chemical structure.

Q. How does temperature affect the performance and longevity of non-stick coatings?

A. Temperature significantly impacts the performance and lifespan of non-stick coatings. These coatings are designed to withstand typical cooking temperatures, generally up to 450-500°F (230-260°C). Exceeding these temperatures, particularly by preheating an empty pan on high heat, can cause the coating to break down rapidly. Prolonged exposure to very high heat can lead to the deterioration of the coating’s structure, causing it to become brittle, lose its non-stick properties, and eventually chip or peel. Maintaining moderate cooking temperatures helps preserve the integrity and longevity of the non-stick surface.

Q. What common practices can damage non-stick surfaces and diminish their effectiveness?

A. Several practices can damage non-stick surfaces, compromising their effectiveness. Using metal utensils can scratch, gouge, or chip the delicate coating, exposing the underlying metal and creating areas where food can stick. Abrasive cleaning pads or harsh chemical detergents can also erode the non-stick layer. Overheating an empty pan is particularly damaging, as it can cause the coating to degrade rapidly. Dishwashing, while sometimes technically permissible, can be harsh due to high temperatures and aggressive detergents, often shortening the pan’s lifespan; hand washing is generally recommended. Additionally, stacking pans without protective dividers can lead to scratches from direct contact.